the front of the tender frames, part of which I primed today

|

the spring hangers and hornblocks

|

the bearings for the tender brake shaft, the crank arm for the water scoop mechanism, and the pins for the safety chains

|

the tender front beam |

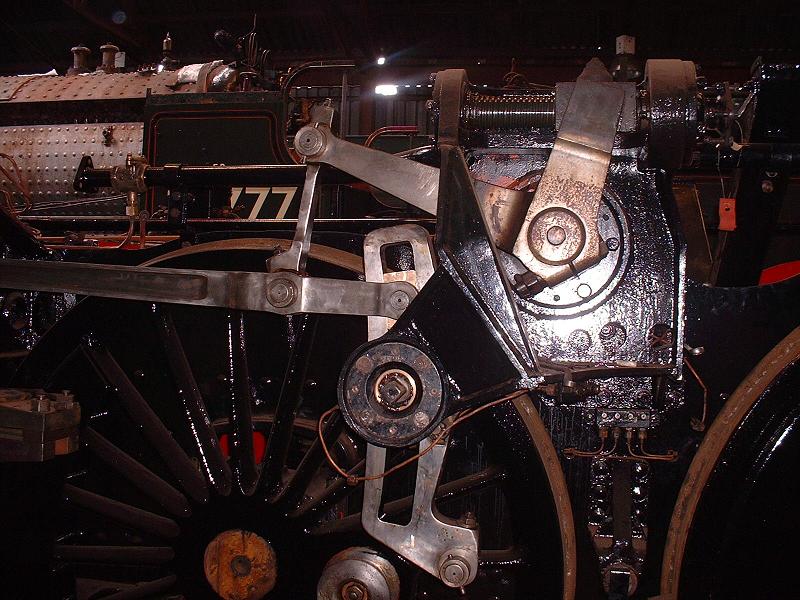

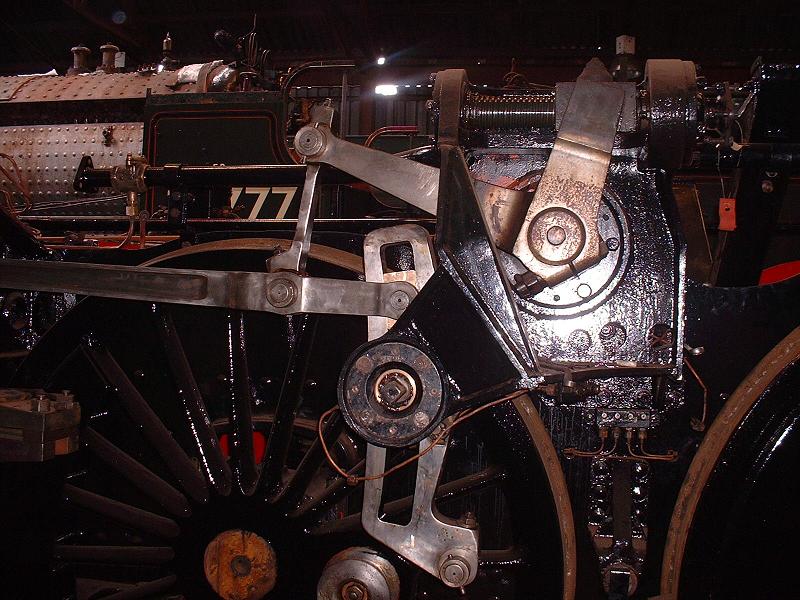

the radius rods have been refitted to the expansion links

|

the rear ring has been fitted to the smokebox, and the manifold cover is being cut out

|

the new cylinder liner in the left-hand cylinder, with cut-outs at the top for the steam ports

|

the cladding on the left-hand cylinder, presumably yet to be painted

|

the rear half of the tender vacuum pipe that I wire-brushed and primed today

|

the tender front panel, showing the recess for the handbrake gears |

the interior of the tank, viewed through an access hole that has been cut in the lower part of the front panel

|

the inside of the coal bunker, viewed from the front. Note the lifting rings, the tool tunnel on the left of the picture and a strengthening girder on the right - most of the vent on the right has been cut away

|

the original smokebox door ring has been fitted to the new smokebox, and a reinforcing plate has been fitted to the inner floor

|

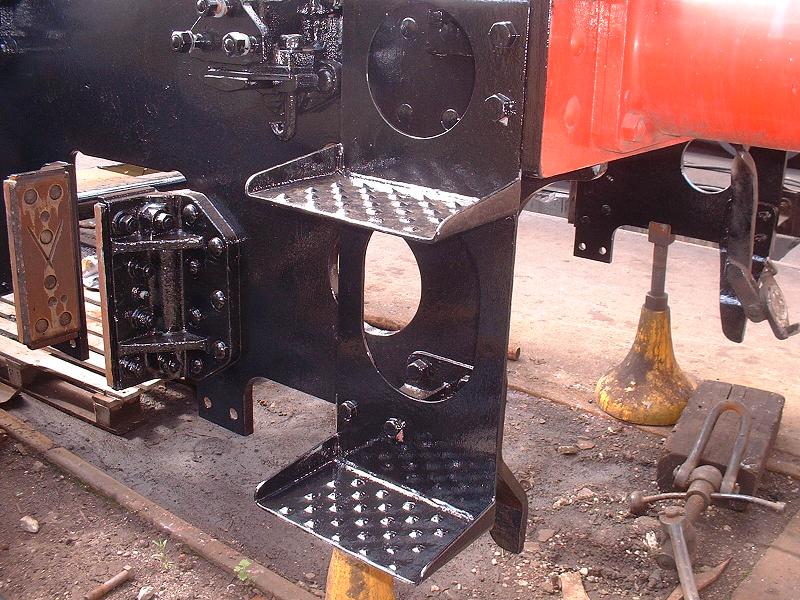

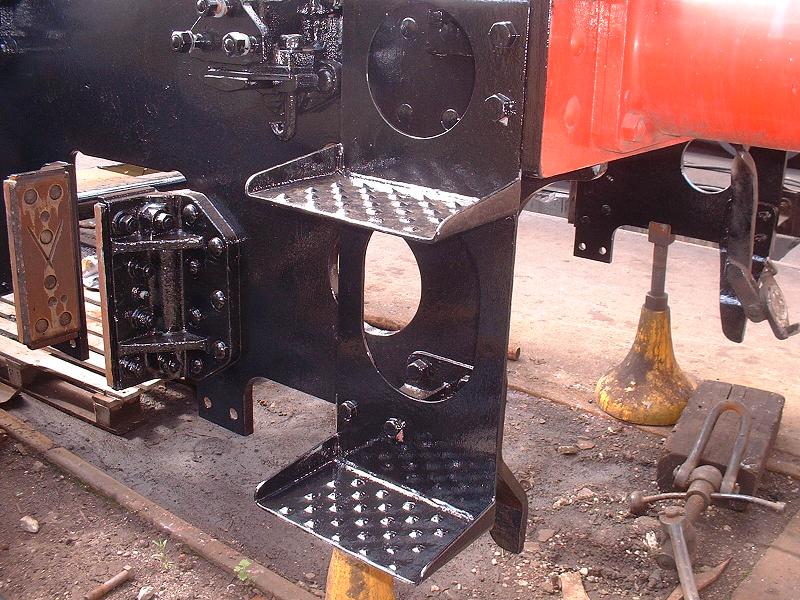

one of the tender steps that I painted today

|

the tender wheels with newly turned tyres - I put a second coat of gloss on the axles today

|

the pistons and piston rods ready to be refitted |

a new valve piston rod being turned in the lathe

|

the spacers that sit between the tender axleboxes and the springs, showing the underside that bears on the axlebox

|

the top rear plate of the tender, showing part of the water filler, the top of the ladder and the step. The yellow object in the foreground is a bucket, not part of the tender |

the right hand side of the bunker, showing one of the tank vents, and the tool tunnel with its front removed

|

a view of the bunker looking forward through the open doors

|