Oliver Cromwell restoration project at the Great Central Railway - Part 6

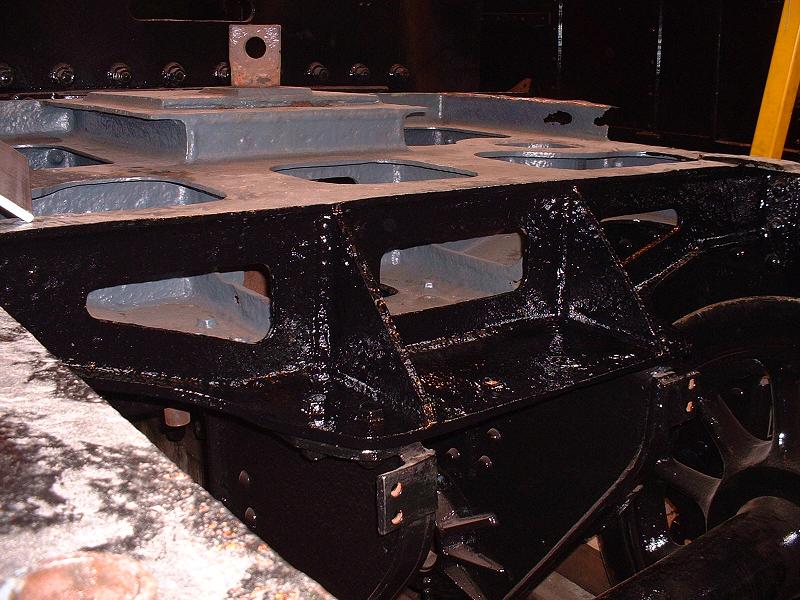

1/9/07 I visited today for my fourteenth working session. Since my last visit the tender wheels have been refitted to the frames and the frames have been moved back into the shed to their correct position behind the locomotive. The tender tank is now out in the yard, but the plan is to fit it back onto the frames within the next few weeks. Work continues on the replacement firebox stays, but the new front tubeplate has still not been delivered and this will delay progress on the boiler if it doesn't arrive soon. I put a coat of black gloss on the two lower tender stretchers, the tender spring hangers, and on the rear tender dragbox and part of the front dragbox - some parts of the front dragbox need new pieces to be welded in to replace parts that have corroded away.

one of the lower tender stretchers that I painted today

|

the front tender dragbox seen from the rear - note the corroded angles on the top that need replacing

|

the rear tender dragbox - note the rubber disks on the drawhook that act as shock absorbers

|

the cut-out section of the new smokebox that fits over the superheater manifold |

the tender tank, finally out in the open air and able to be photographed

|

also seen at the GCR today - the BR Standard class 2 in steam

|

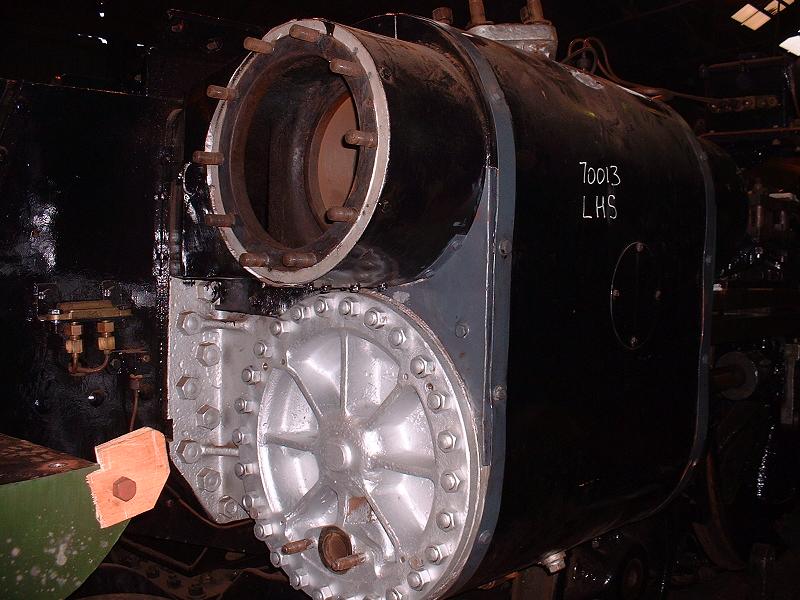

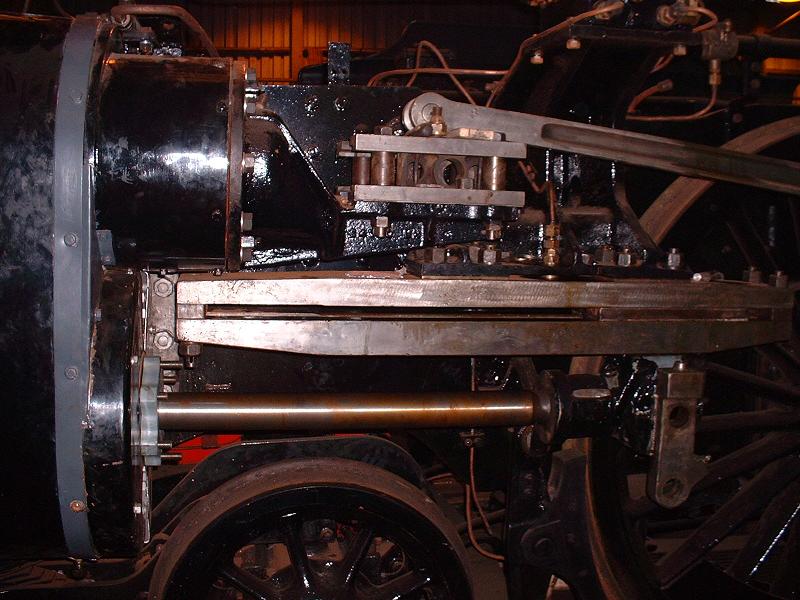

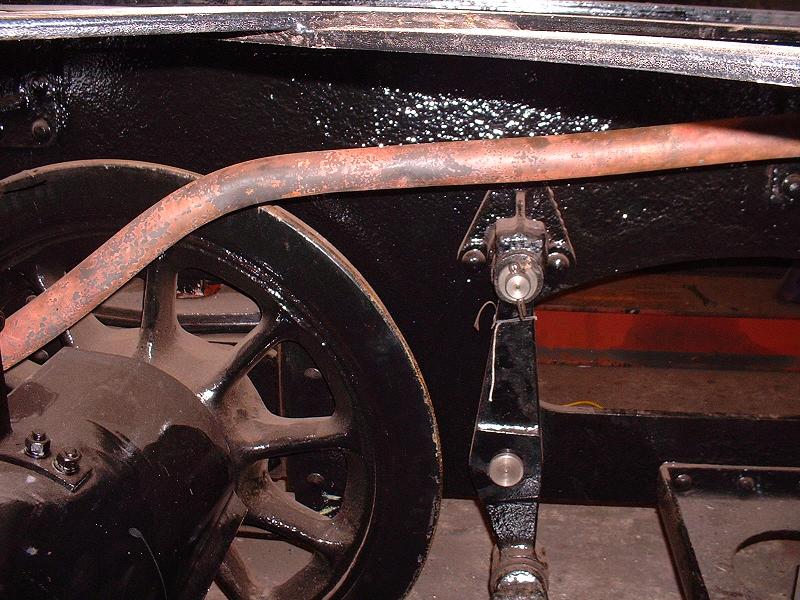

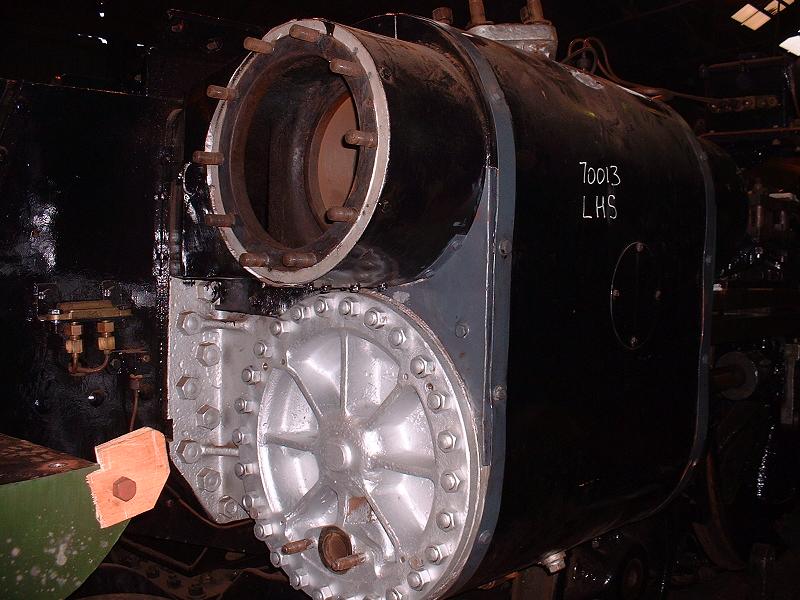

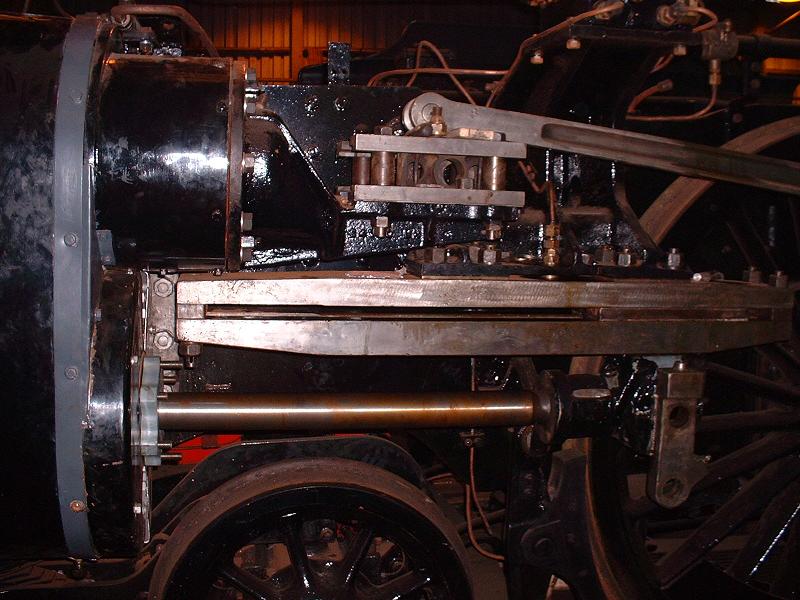

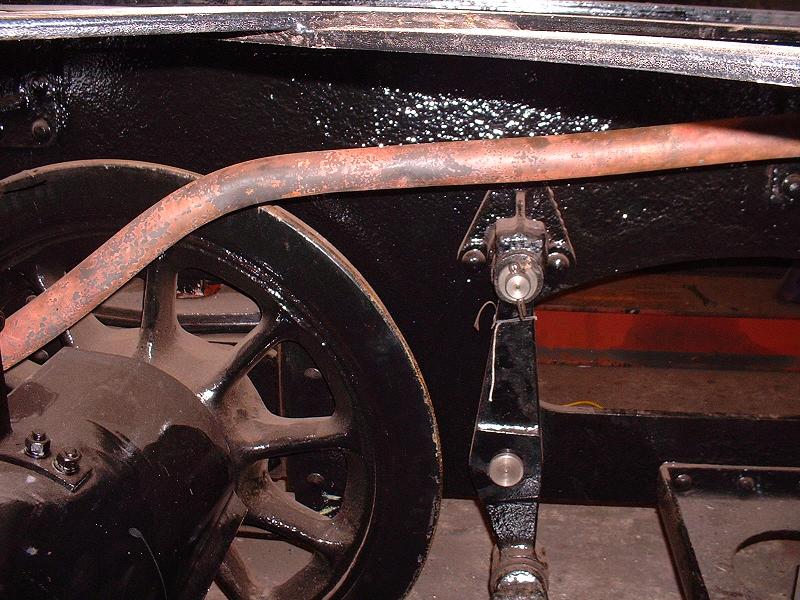

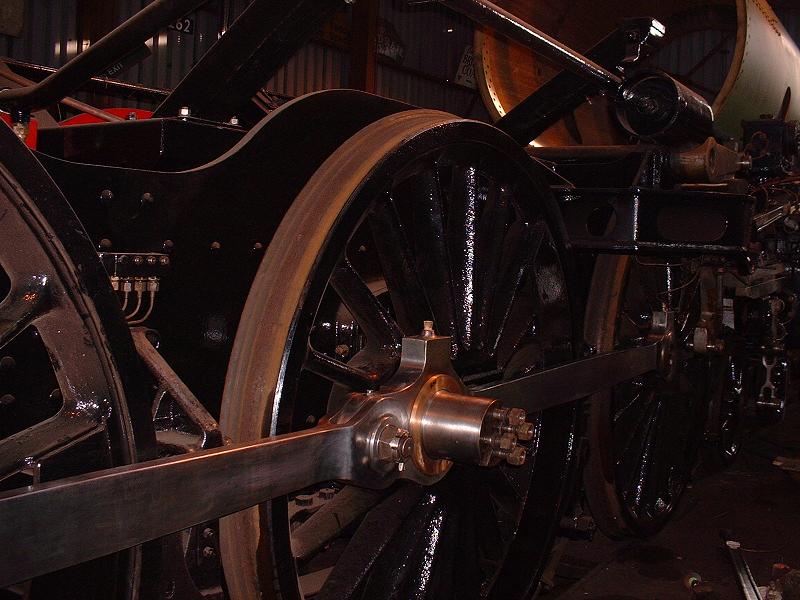

10/11/07 I visited today for my fifteenth working session. Since my last visit the pistons and cylinder covers have been refitted, along with the return cranks and eccentric rods. The coupling and connecting rods are away being refurbished. The tender tank is back in the shed, and work has started on the paintwork on one side. The new smokebox is complete, but the new front tubeplate for the boiler has still not been delivered. I put a coat of undercoat on miscellaneous small parts including the valve end cladding pieces.

the pistons and cylinder end covers have been refitted

|

the piston rod and crosshead

|

the return crank and eccentric rod

|

the view through the firedoors showing many new screwed stays

|

the opening sections of the cab roof seen from the front with the dovetailed rails that they slide on

|

the ashpan, yet to be restored

|

the front of the tender frames with the intermediate buffers refitted |

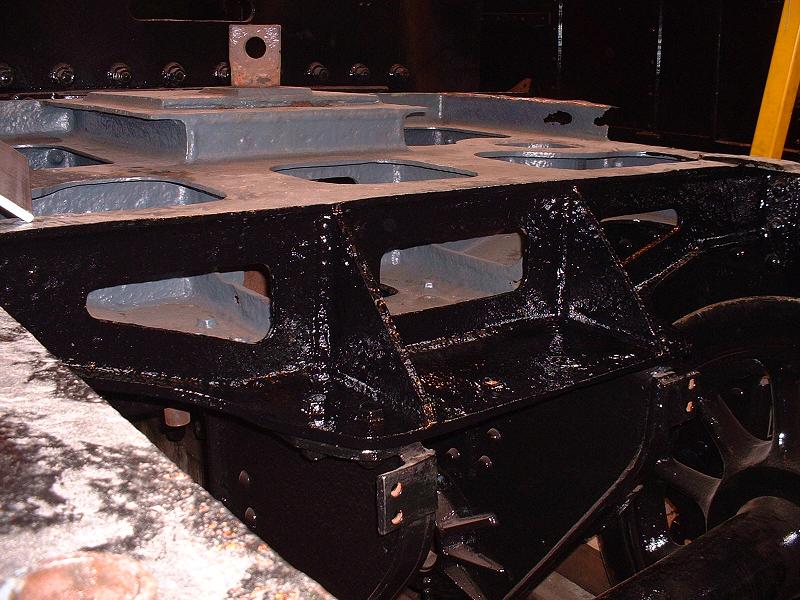

the cross braces on the very dusty tender frames - note also black-painted plywood pads all around the outside for the tank to rest on

|

one of the tender brake hangers - the brake blocks have not yet been refitted

|

the tender brake cylinder, and the new guard over the front axle |

the right hand side of the tank, rubbed down for painting and showing the layers of paint that have been applied over the years

|

12/1/08 I visited today for my sixteenth working session. Since my last visit the coupling rods have been refitted, the tender tank has been reinstalled on the frames and the new smokebox has been temporarily fitted to the saddle. Work continues apace on the firebox stays and foundation ring rivets, but the new front tubeplate for the boiler has still not been delivered, although I'm told that it is expected next week. I derusted and polished the right hand coupling rods using a flap wheel in an electric drill and lots of elbow grease.

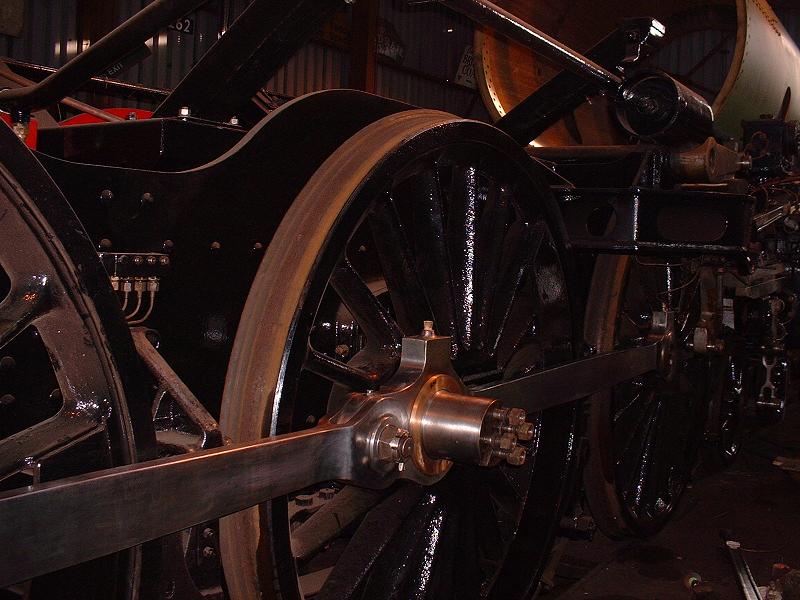

the right hand coupling rods that I polished today

|

the tender tank restored to the

frames, with some of the lower platework replaced and a coat of undercoat on the tender side

|

the new smokebox fitted temporarily to the saddle

|

the right hand return crank and eccentric rod, polished today by another volunteer

|

also seen at the GCR

today - King Arthur class "Sir Lamiel" outside the engine shed

|

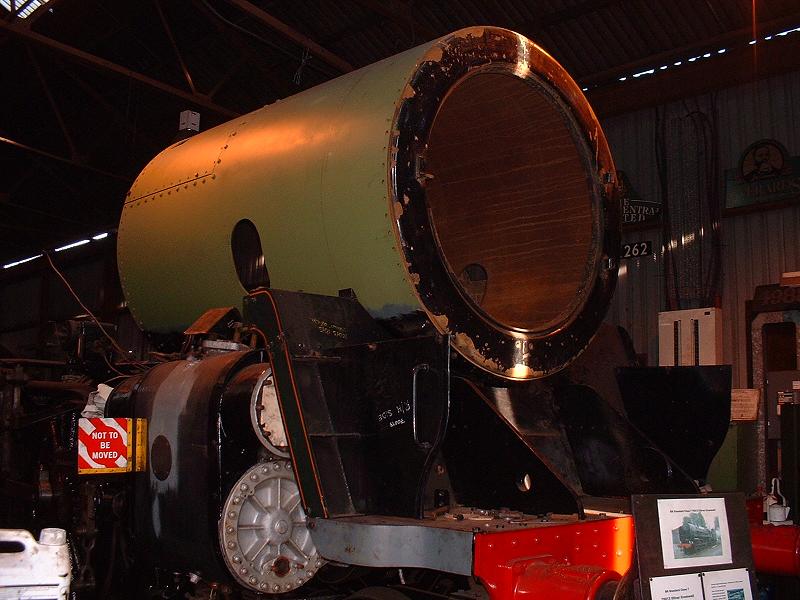

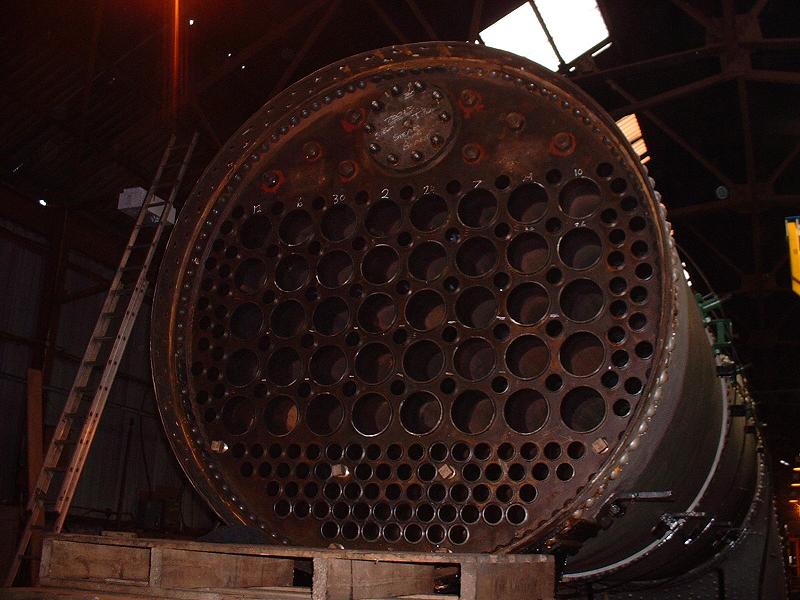

15/3/08 I visited today for my seventeenth working session. A lot of progress has been made since my last visit - the boiler has been completed and was having an initial 50psi hydraulic pressure test today, the motion gear, lubricators and cylinder drain cocks have been refitted, and one side of the tender tank has been glossed. I spent the day removing rust from the inside of the boiler cladding plates. Assuming that the various small leaks in the boiler can be fixed in time, I gather that the plan is to do the formal hydraulic pressure test on Tuesday, then temporarily fit the boiler to the frames so that it can be lined up and rivetted to the smokebox, then remove the boiler and smokebox to the yard outside so that the initial steam tests can be done off the frames. The target is still to have the locomotive steaming next month!

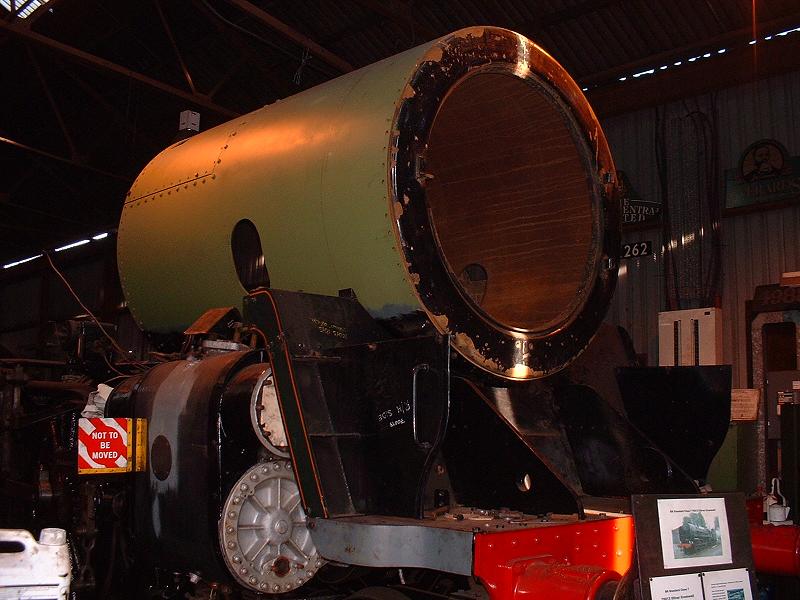

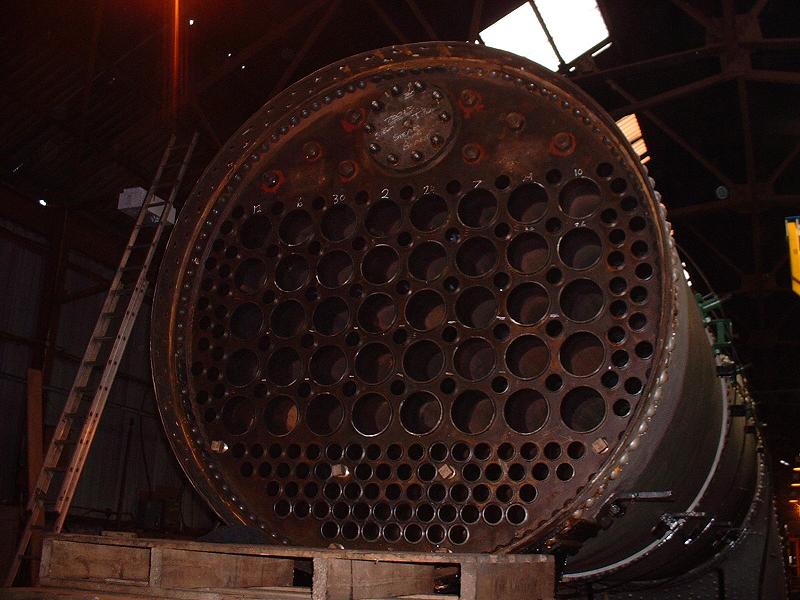

the new front tubeplate with the flues and superheater tubes fitted

|

the side of the firebox - note the

trickles of water running down from slight leaks on the top during the hydraulic test

|

the experts working on top of the firebox to tighten the leaking stay heads

|

the test gauge showing 50psi of pressure in the boiler - the boiler is filled to the brim and the pressure is cranked up with a handpump, just as on a model boiler

|

the boiler cladding plates that I

worked on today

|

the two halves of the top throatplate cladding, undercoated

|

the right hand motion gear with the primed dome cover in the foreground

|

the tender tank resplendent in its dark green gloss

|

the ashpan which another volunteer derusted today. The interior will be left unpainted, and the outside will be covered in a special heat-resistant paint

|