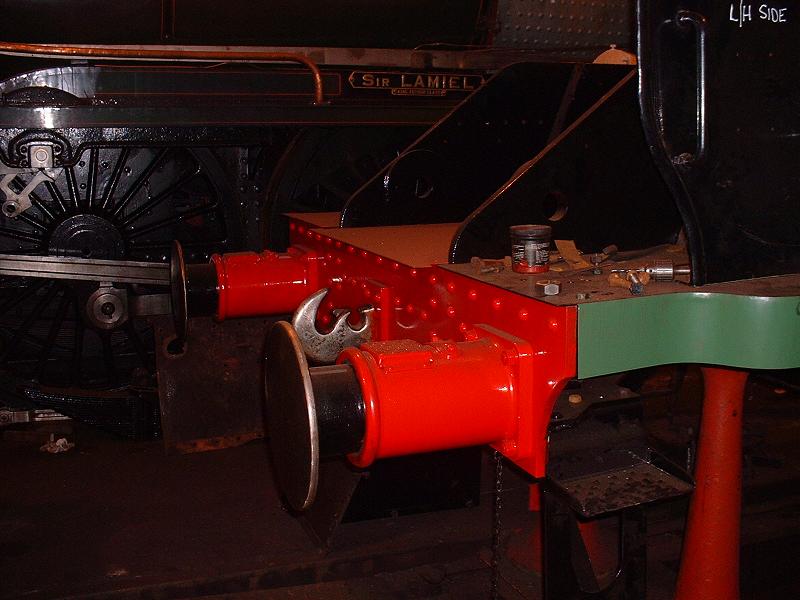

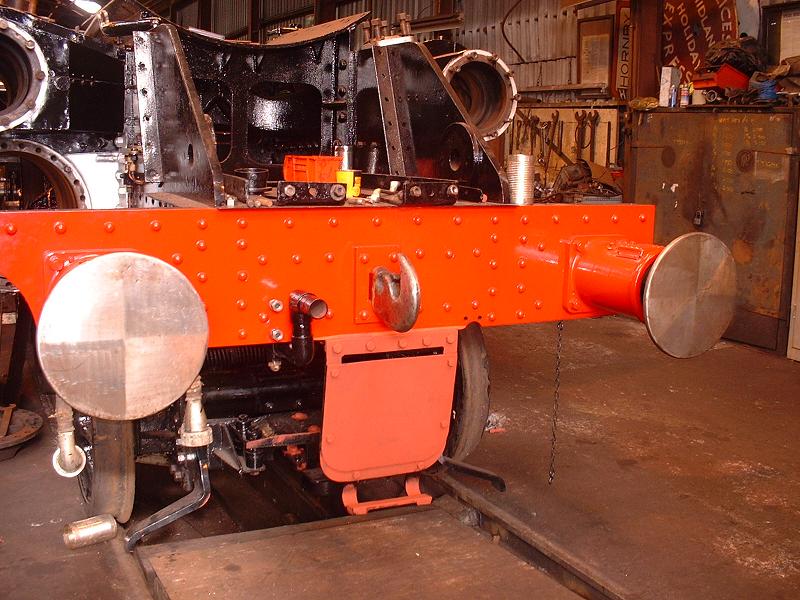

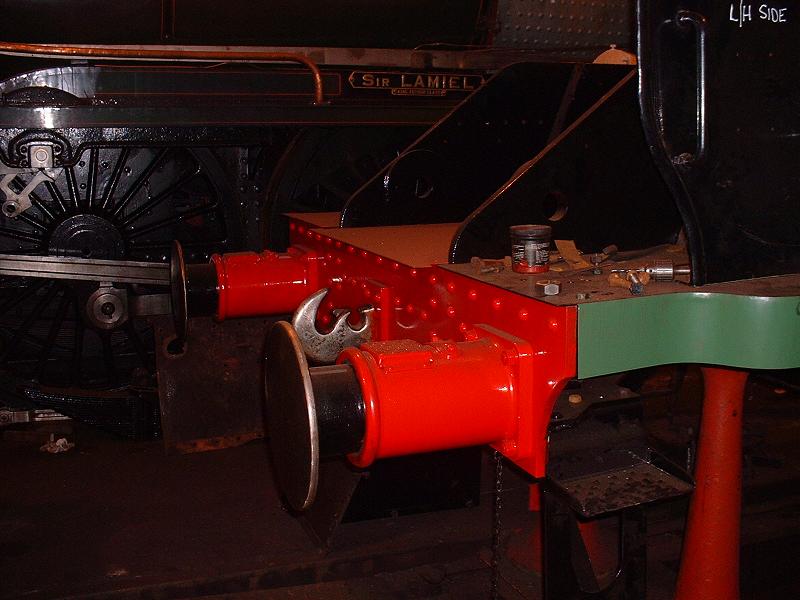

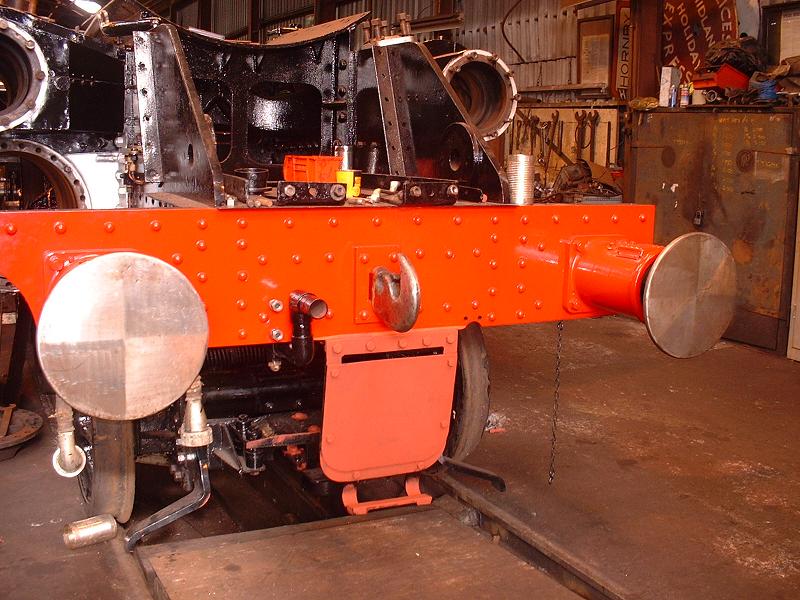

the buffers fitted to the new front buffer beam - note also King Arthur class 'Sir Lamiel' in the background

|

three of the loco brake carriers that I painted today

|

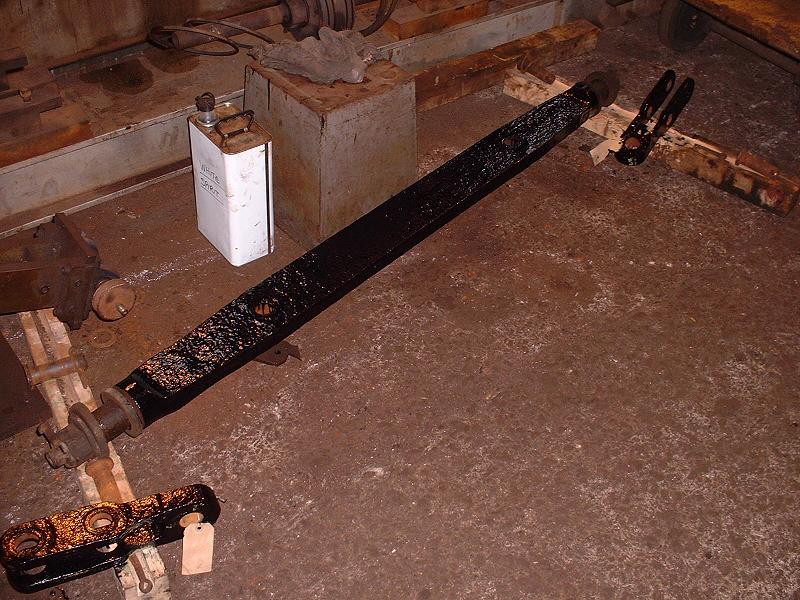

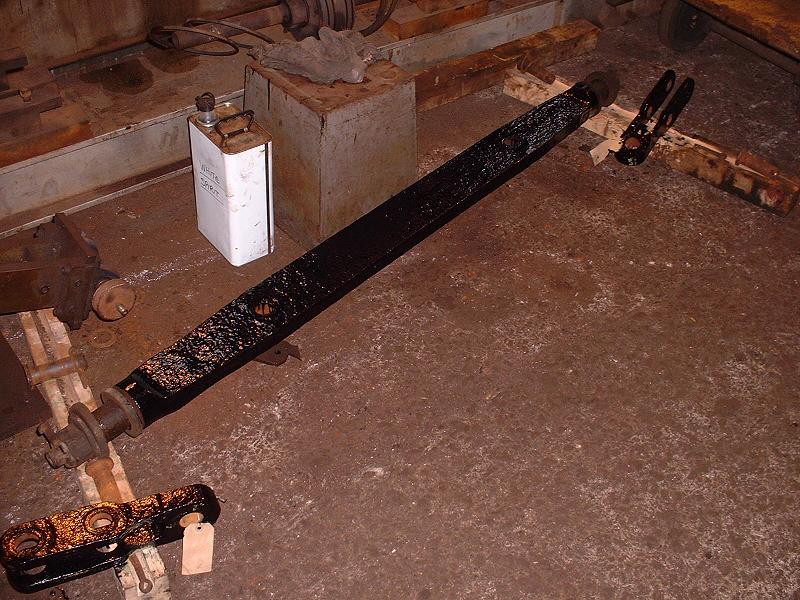

the front tender brake stretcher and links that I painted today

|

the new smokebox out in the yard behind the shed, having its holes cut |

one of the lubricator boxes, showing the handle for manual priming

|

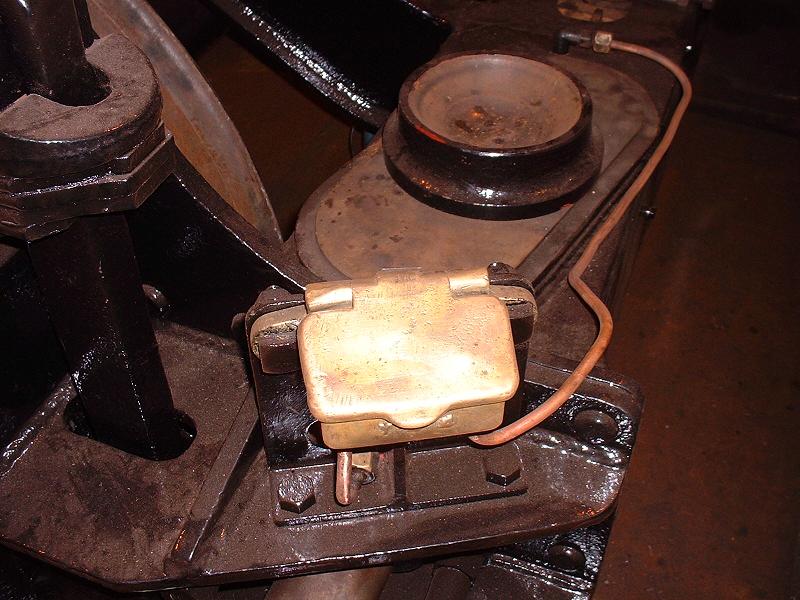

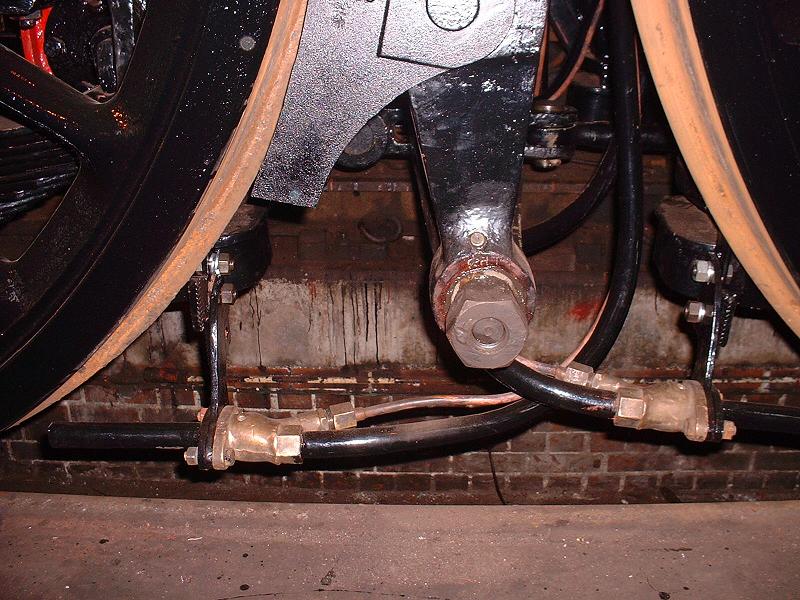

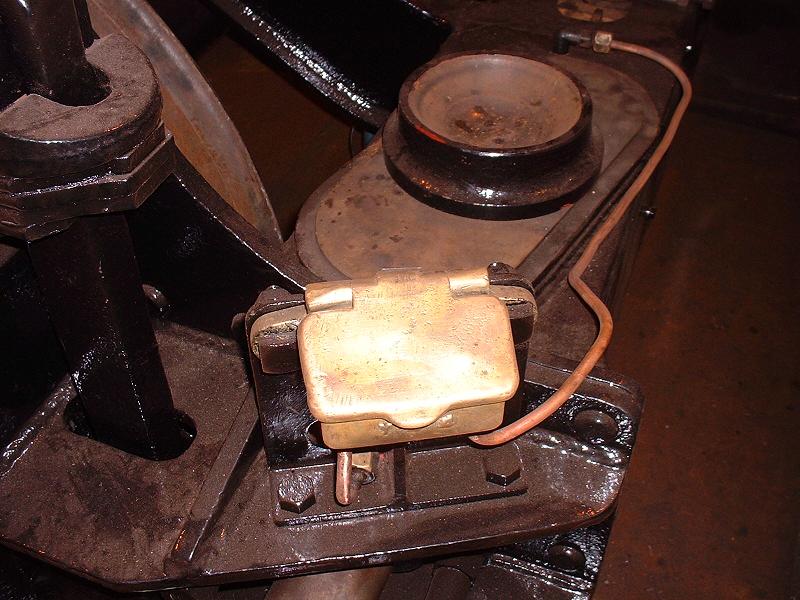

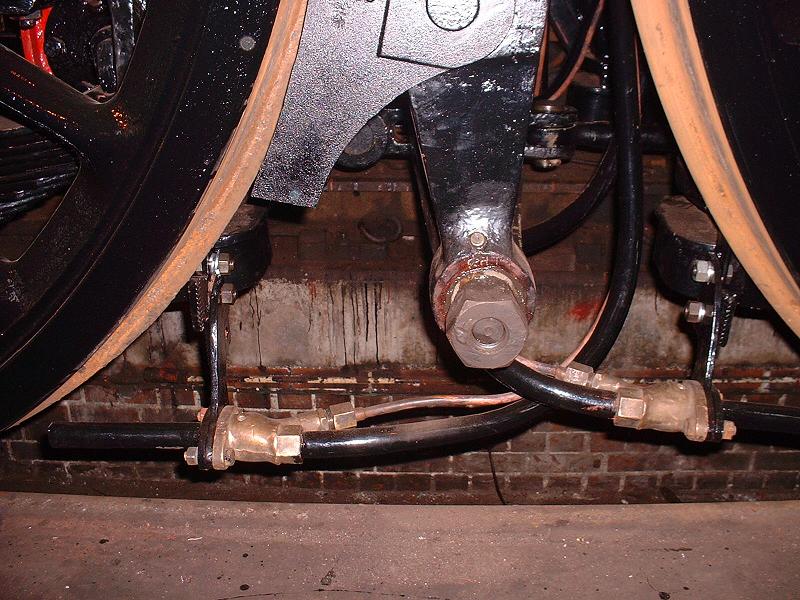

one of the brass oil boxes on the rear corners of the pony truck

|

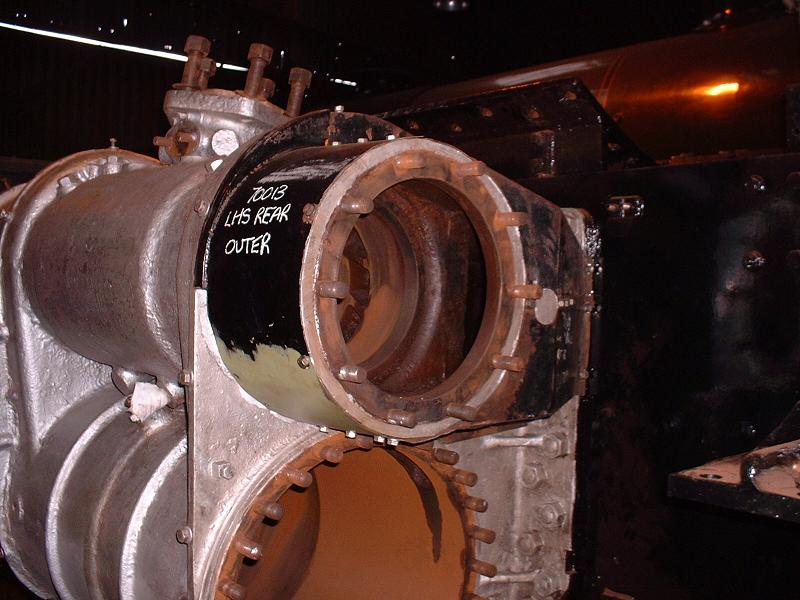

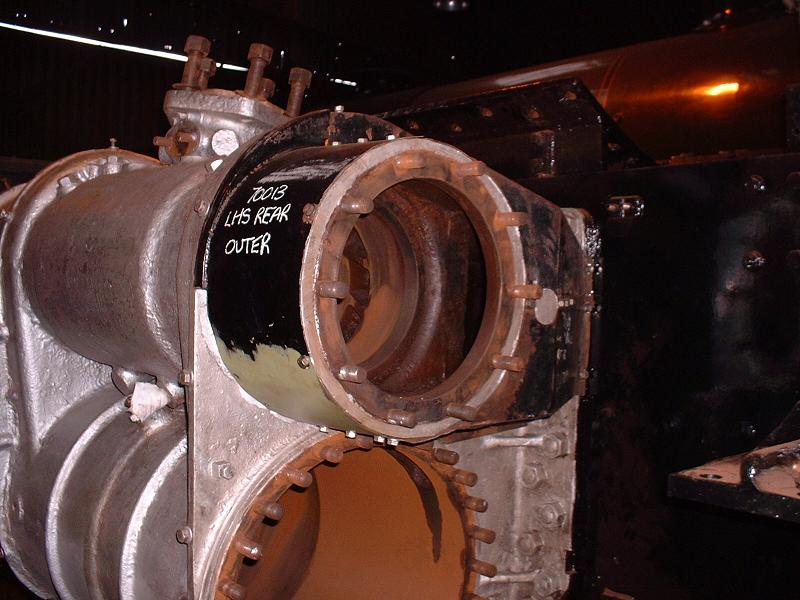

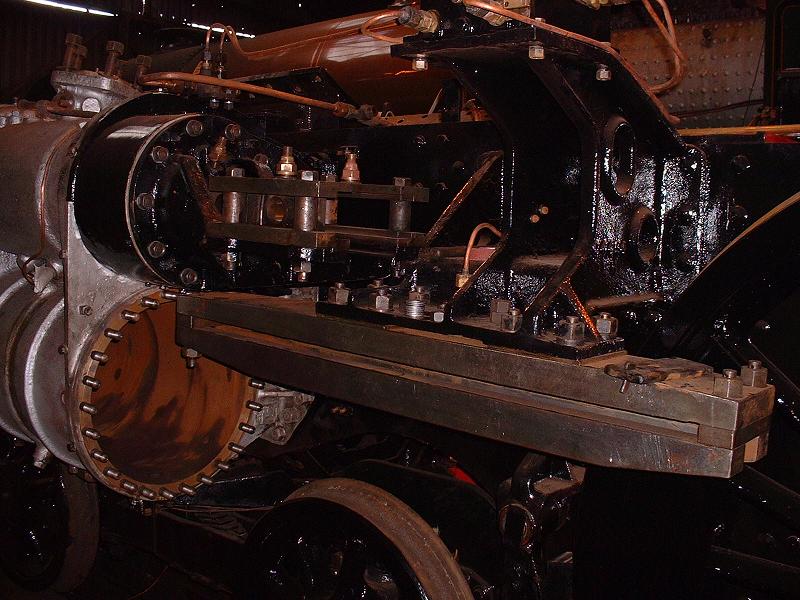

the cleading fitted to the rear end of the valve chest - note the insulating material inside the sheet metal |

the right-hand rear valve cover and the slides for the valve crosshead. The curved plate inside the valve chamber presumably helps to direct the exhaust steam inwards towards the blastpipe

|

the tender vacuum hose support stay

|

the bogie, driving wheels and pony have been refitted to the frames, along with the brake gear and slidebars

|

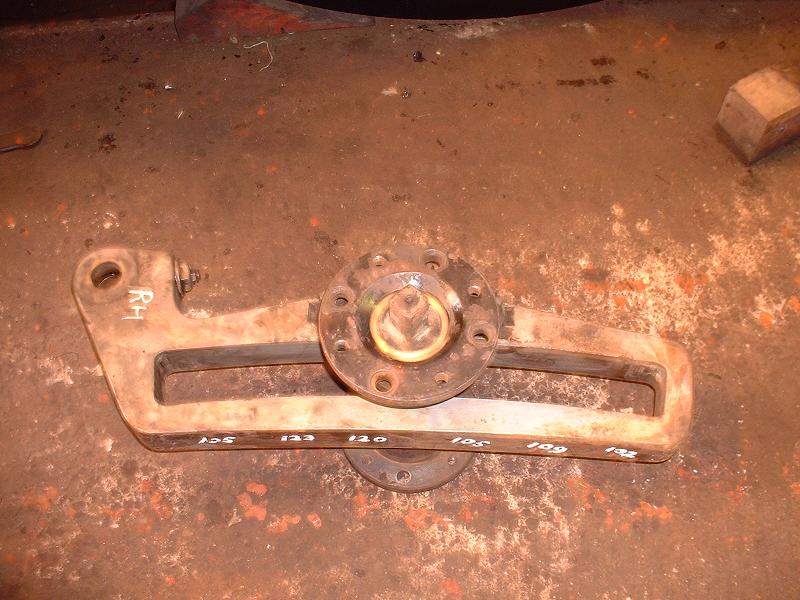

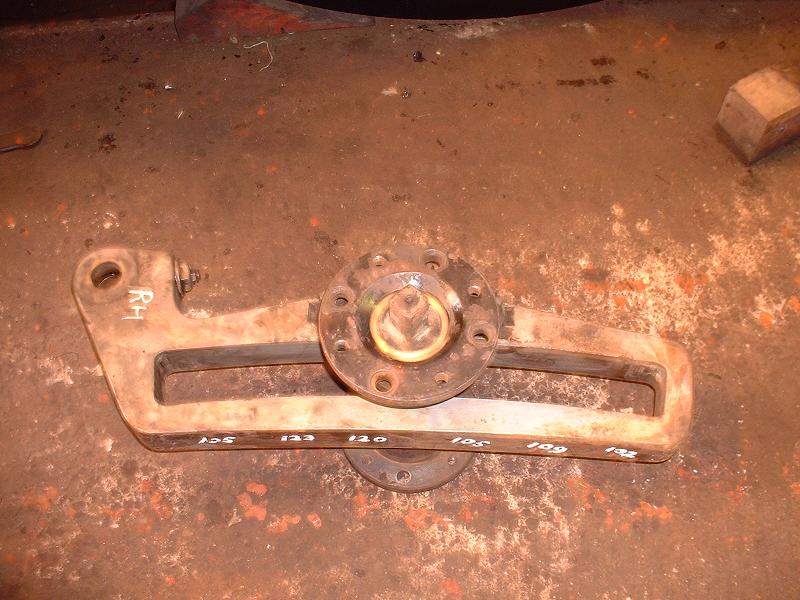

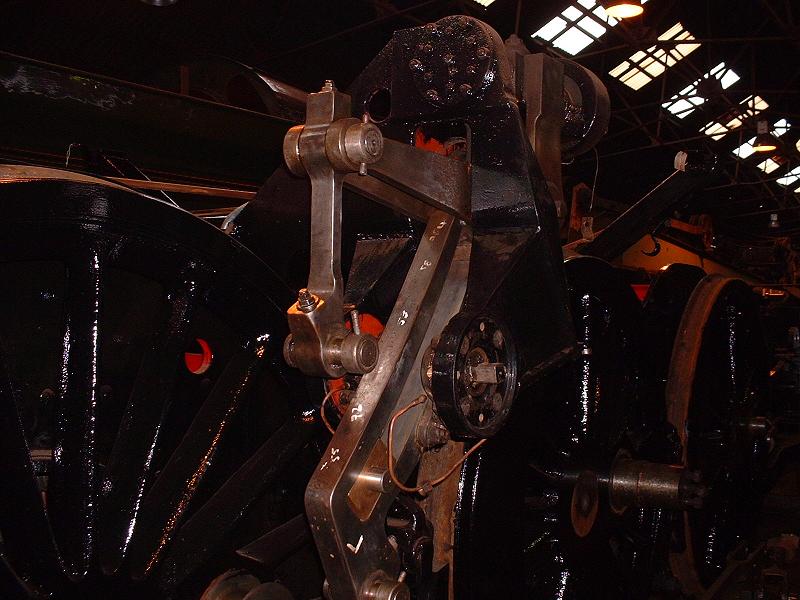

one of the expansion links

|

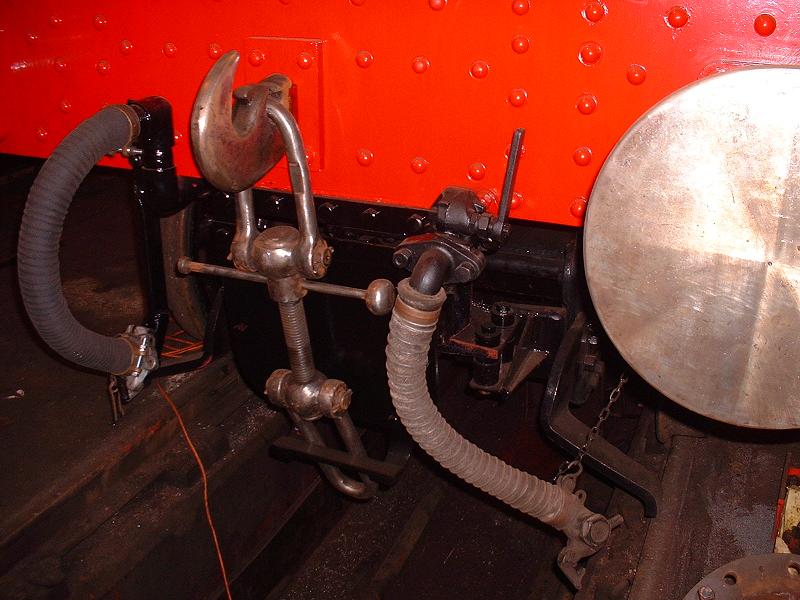

the buffer beam with 'bash plate' and vacuum pipe |

the tender frames that I cleaned with a needle gun today. The top stretcher has been removed and a new one was being fabricated today

|

the inside of the left hand (driver's) side of the cab, with the mounting bracket for the reversing gearbox |

the right hand (fireman's) side of the cab. Note that there are fewer rivets than on the driver's side

|

the removable section of the old smokebox, showing the cutouts for the regulator cover and the regulator spindle mounting

|

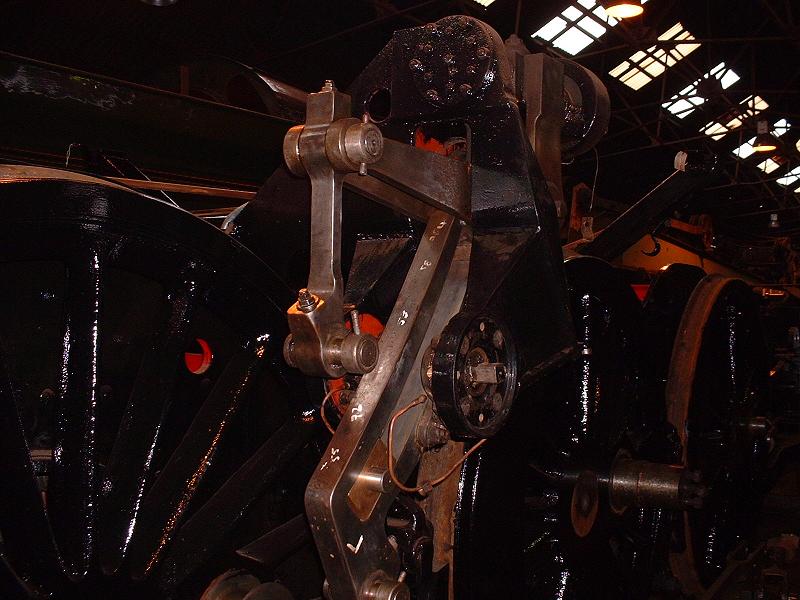

the expansion links, die blocks and lifting levers have been refitted

|

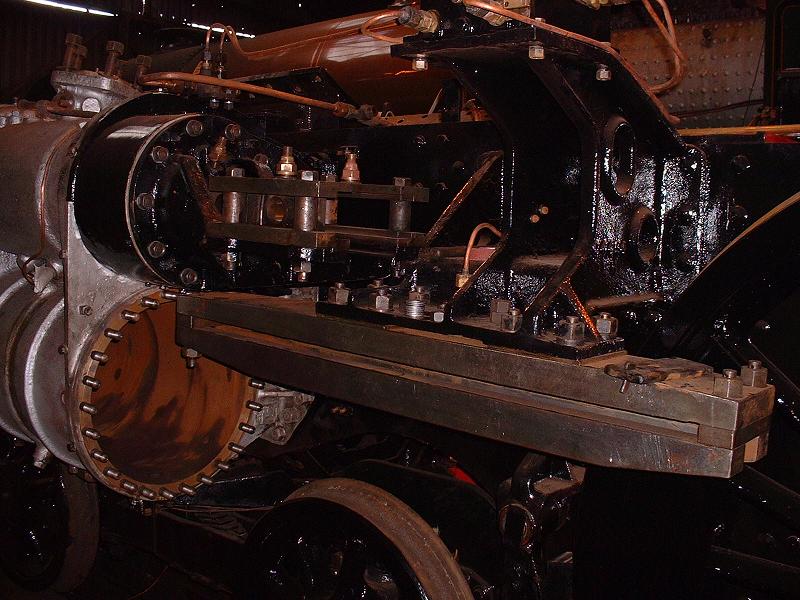

the slidebars and valve guides

|

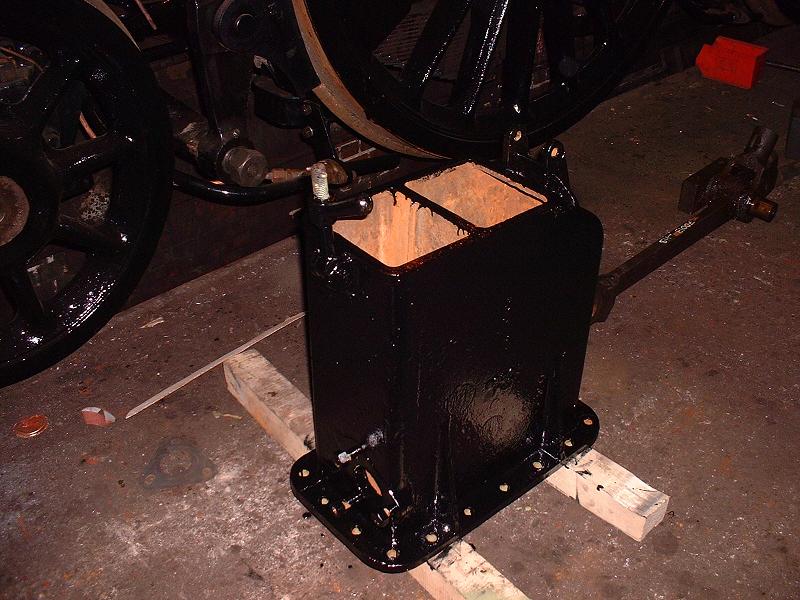

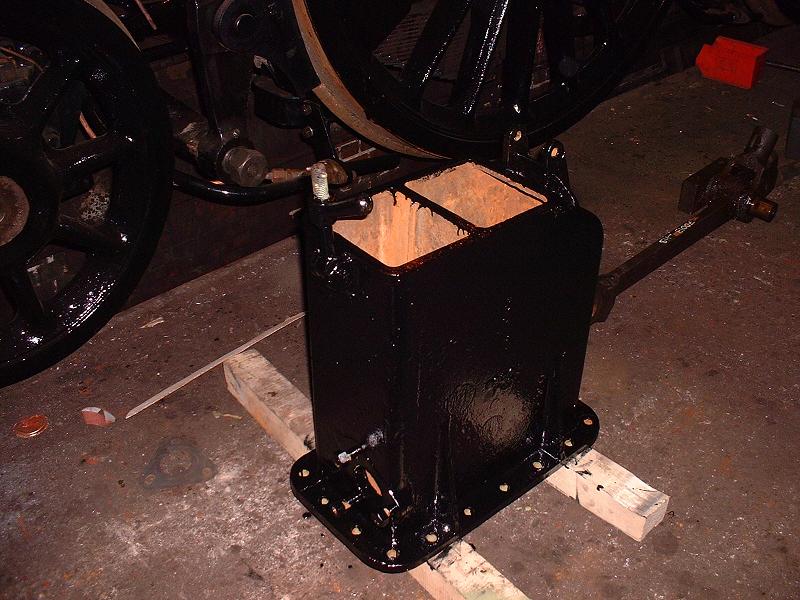

one of the filter boxes that I painted today

|

the fittings on the rear beam |

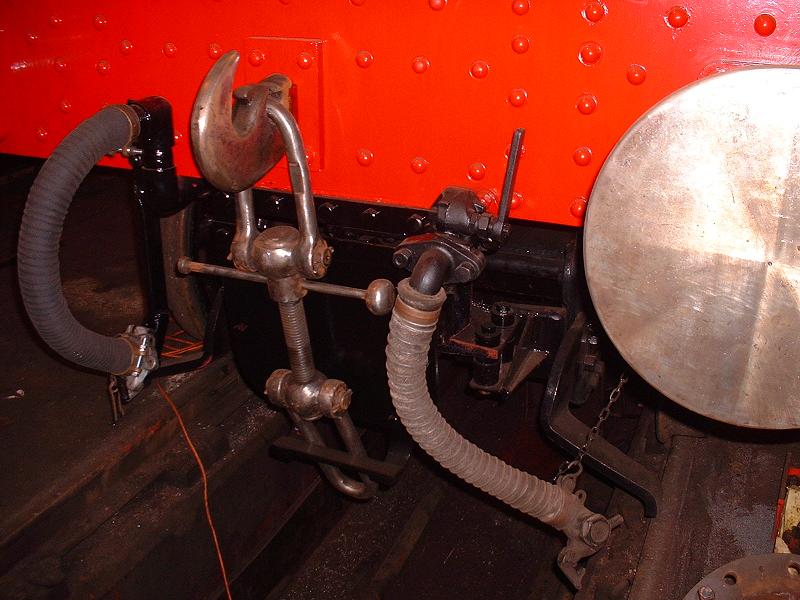

the steam heating hose and vacuum pipe on the front buffer beam

|

a view forward along the top of the frames, showing the two sand boxes and the supports for the running boards |

the sanding pipes between the right leading and driving wheels

|