Kit 1 - Tender Frames

3/11/05

Having visited the Modelworks factory a few weeks ago, and heard good reports from another Britannia builder and from the local model engineering society in St Albans, I took the plunge and ordered the Modelworks Britannia.

4/11/05

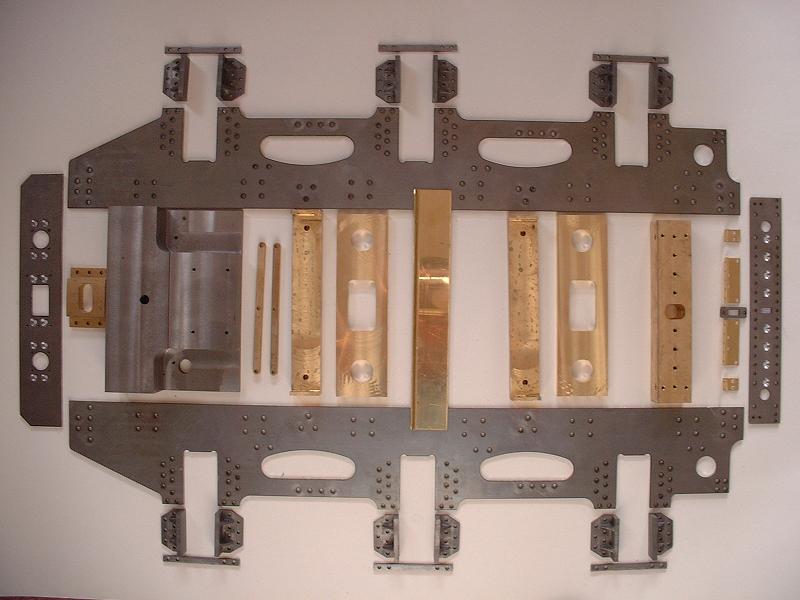

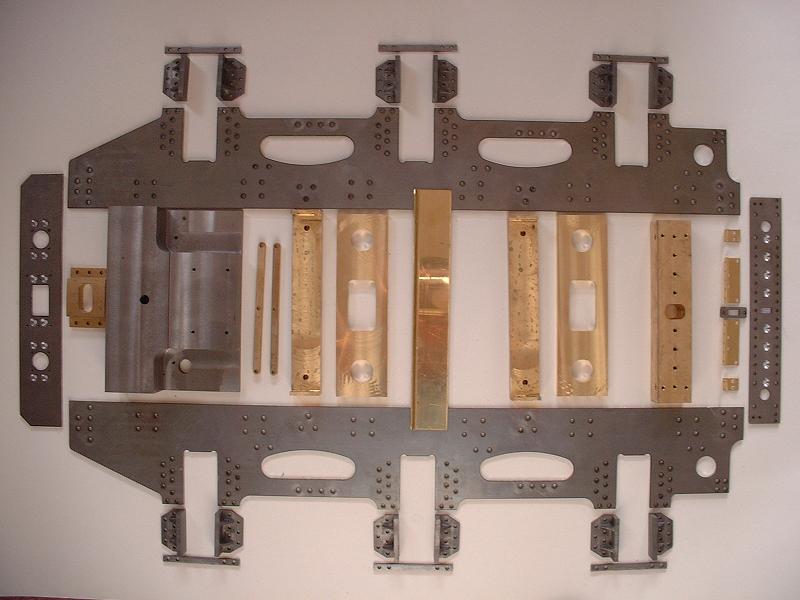

Kit 1, the tender frames, arrived at 8am! Opened it up and checked the contents - nicely packaged, although one item, the tender platform, was missing. I phoned Debbie at Modelworks and she promised to send a replacement. I'm impressed with the quality of the materials and the machining - it looks as though it should go together very smoothly. The axle horn cheeks are cast iron rather than brass as in the earlier Winson version of the kit.

4/11/05

Kit 1, the tender frames, arrived at 8am! Opened it up and checked the contents - nicely packaged, although one item, the tender platform, was missing. I phoned Debbie at Modelworks and she promised to send a replacement. I'm impressed with the quality of the materials and the machining - it looks as though it should go together very smoothly. The axle horn cheeks are cast iron rather than brass as in the earlier Winson version of the kit.

I made email contact with Richard, another Britannia builder based in Rotherham. Richard has completed the first 7 kits and has kindly offered to give advice if I need it. The main question in my mind at the moment is how and when to paint it, but I can afford to take a little time to research this.

6/11/05

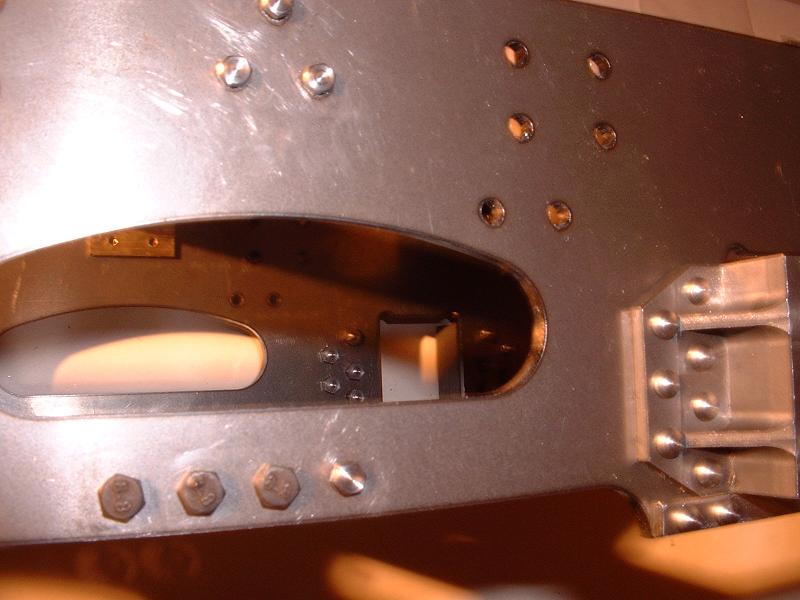

I loosely assembled the frames, stretchers and buffer beams and one set of axle horn cheeks and horn stay to check how it all fits together. I need to buy some small files to clean up some of the laser-cut bolt holes in the frames, and a nut spinner to save my fingers. Richard has recommended buying M3 bolts with smaller heads to get a better scale effect, so I shall do this before securing anything permanently. I see that imitation rivet-head bolts have been supplied for the horn cheeks and horn stay to give a more accurate result - but perversely the horn stays on the full-size Britannia seem to have hexagonal bolt-heads, judging by this picture of the axle box of the full-size Britannia.

7/11/05

I visited Chronos in Dunstable to buy some files and other hand tools, and ordered some M3 bolts with smaller heads from Polly Model Engineering. I cleaned up the holes in the frames and assembled the horn cheeks, stays, stretchers and buffer beam mountings. I must say that the frames do not look at all bad with the bolts supplied, but I will decide what to do when the smaller bolts arrive.

8/11/05

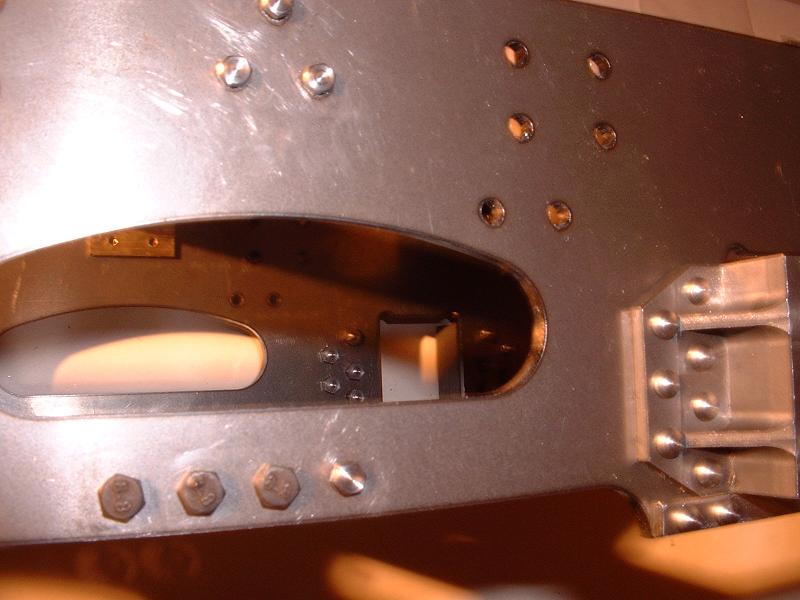

The M3 bolts arrived this morning - excellent service. The heads are 4mm across flats instead of 5.5mm, and noticeably better quality, so I shall use them for all the tender frame bolts, including the horn stays. The snag is that they only come in 15mm length, so I shall have a lot of cutting to do. Here is a photograph of the small (silver) and standard (black) bolts for comparison, also showing the rivet-head bolts on the horn cheeks and stays.

8/11/05

The M3 bolts arrived this morning - excellent service. The heads are 4mm across flats instead of 5.5mm, and noticeably better quality, so I shall use them for all the tender frame bolts, including the horn stays. The snag is that they only come in 15mm length, so I shall have a lot of cutting to do. Here is a photograph of the small (silver) and standard (black) bolts for comparison, also showing the rivet-head bolts on the horn cheeks and stays.

9/11/05

I cut 50 of the new bolts to length using a cut-off wheel in my Dremel, and bolted up the frames to the stretchers and buffer beam mountings. I went along to the St Albans Model Engineering Society's monthly meeting and met other enthusiasts, including Tim who has recently completed the Modelworks 5700 pannier tank engine and has described the build on his website at www.whiteice.co.uk.

10/11/05

I started fixing the rivets in the buffer beam - I decided to rivet them properly with a rivet snap instead of using Loctite, countersinking the holes on the back of the buffer beam so that the rivets could be filed flush. I also ordered kit 2 today.

11/11/05

Kit 2 arrived at 8am, along with the missing tender platform from kit 1. I checked the contents of kit 2 and put it aside, and filed the rivets flat on the back of the buffer beam.

11/11/05

Kit 2 arrived at 8am, along with the missing tender platform from kit 1. I checked the contents of kit 2 and put it aside, and filed the rivets flat on the back of the buffer beam.

12/11/05

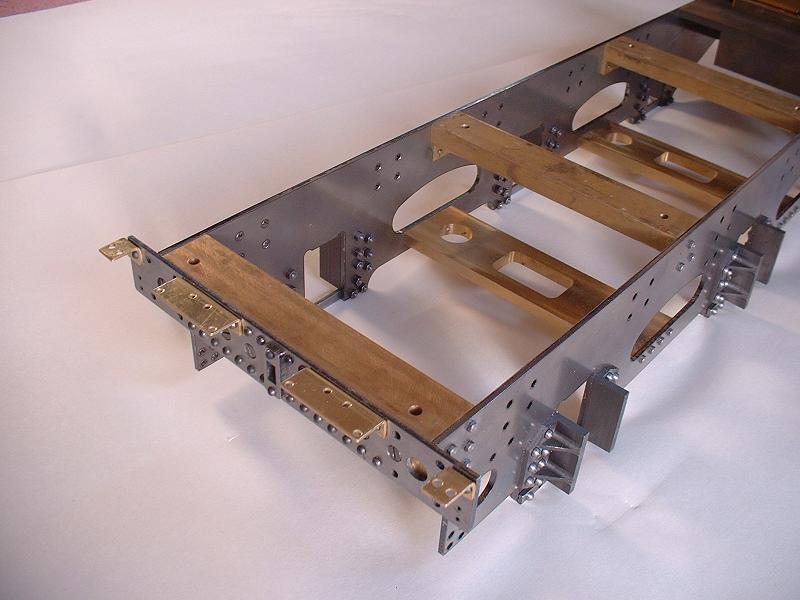

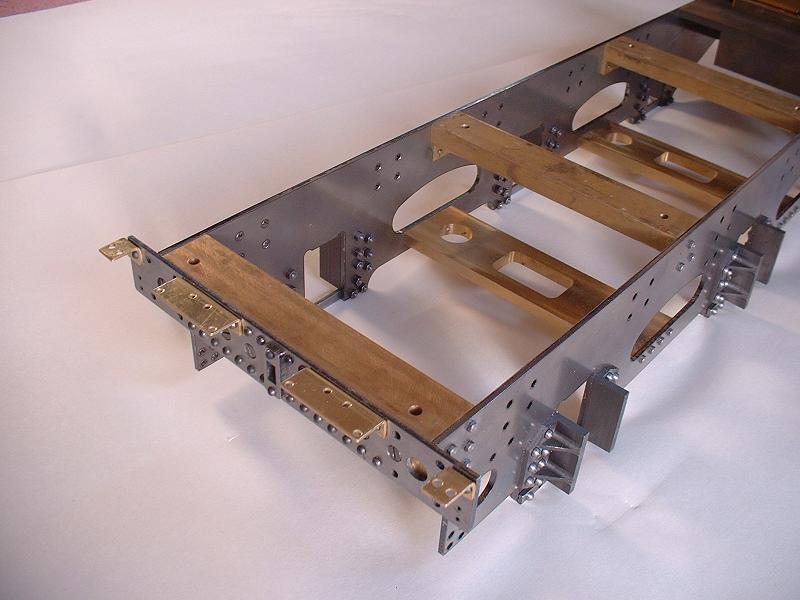

I completed kit 1 by bolting on the buffer beam and the tender platform and top deflector plate. These pictures show the front and rear views of the completed kit.

4/11/05

Kit 1, the tender frames, arrived at 8am! Opened it up and checked the contents - nicely packaged, although one item, the tender platform, was missing. I phoned Debbie at Modelworks and she promised to send a replacement. I'm impressed with the quality of the materials and the machining - it looks as though it should go together very smoothly. The axle horn cheeks are cast iron rather than brass as in the earlier Winson version of the kit.

4/11/05

Kit 1, the tender frames, arrived at 8am! Opened it up and checked the contents - nicely packaged, although one item, the tender platform, was missing. I phoned Debbie at Modelworks and she promised to send a replacement. I'm impressed with the quality of the materials and the machining - it looks as though it should go together very smoothly. The axle horn cheeks are cast iron rather than brass as in the earlier Winson version of the kit.